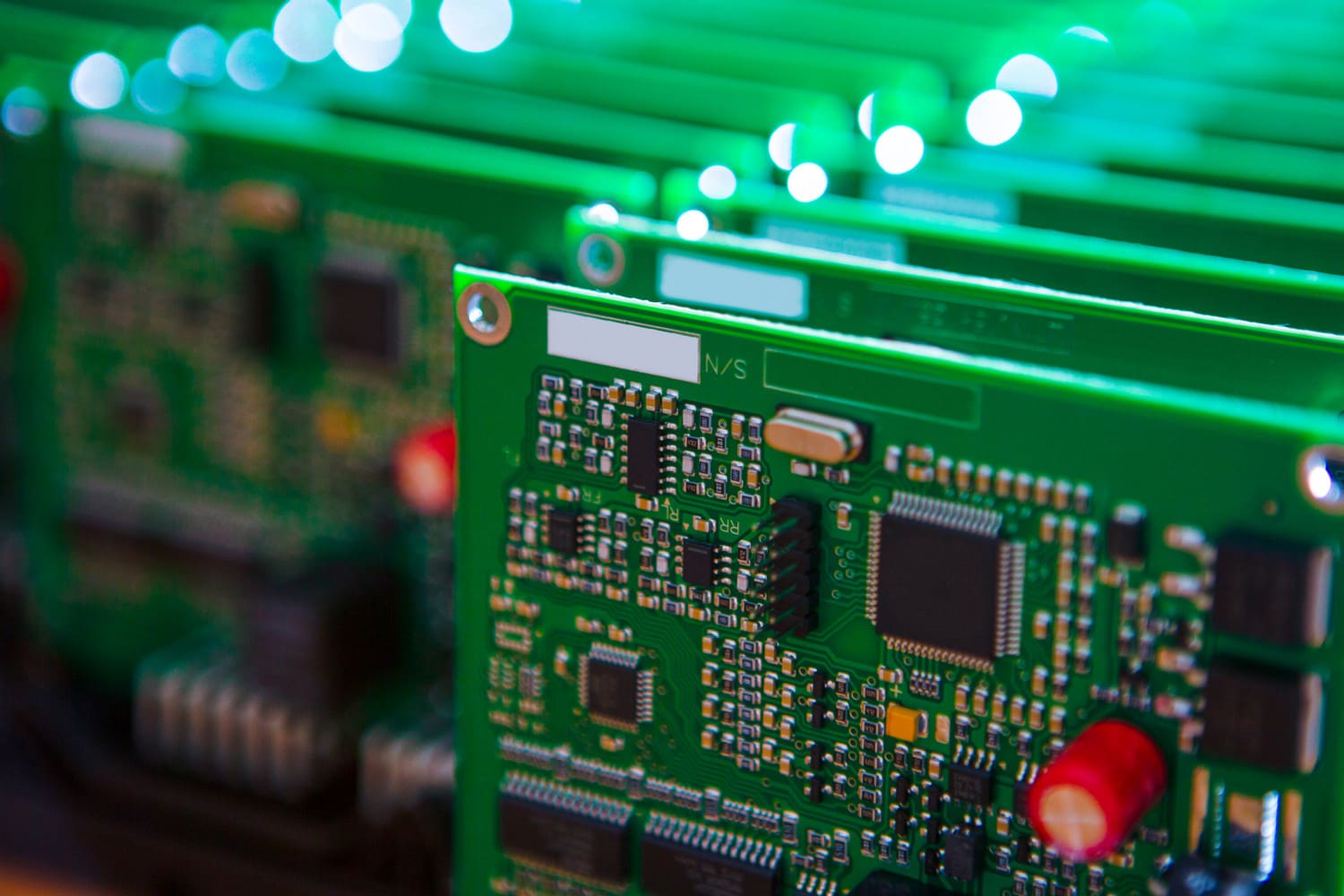

Circuit boards, often referred to as printed circuit boards (PCBs), are the unsung heroes of modern electronics. They serve as the backbone for electronic devices, allowing various components to connect and communicate. While you might think of circuit boards as simply green, they can come in a variety of colors, each with its own unique purpose and characteristics. In this blog, we’ll explore the reasons behind the colors of circuit boards and delve into why the classic green PCB is so prevalent.

The Colors of Circuit Boards

- Classic Green PCBs: Green is the most iconic color for PCBs, and you’ve probably seen it countless times without realizing why it’s so prevalent. The green color comes from the solder mask, a protective layer that covers the copper traces on the PCB. This green solder mask is a result of tradition rather than any specific technical requirement.

To learn more about why PCBs are typically green, check out this insightful article on why are circuit boards green.

- Red PCBs: Red PCBs are another common color. They have no distinct advantage over green PCBs in terms of performance, but red PCBs are often used for aesthetic reasons or to indicate a specific purpose, such as power-related circuits or prototypes.

- Blue PCBs: Blue PCBs are popular among enthusiasts and hobbyists. These boards are visually appealing and often used in projects where aesthetics are important. They can also help distinguish different sections of a complex circuit.

- Black PCBs: Black PCBs are synonymous with high-end, premium electronics. The black solder mask is often associated with products that demand a sleek and sophisticated appearance. They are often used in industries like gaming, audio equipment, and high-performance computers.

- White PCBs: White PCBs are less common but have started gaining popularity, especially in consumer electronics. White PCBs can give a clean and minimalistic look to the end product.

- Yellow and Purple PCBs: Yellow and purple PCBs are rare but not unheard of. They are chosen based on the manufacturer’s preferences or to convey uniqueness in a product.

- Multilayer PCBs: Multilayer PCBs can have a variety of colors, often denoting different layers for easier assembly and troubleshooting. These colors are not visible externally, but they help PCB assemblers during the manufacturing process.

Why Are Circuit Boards Green?

Now, let’s dive deeper into the classic green PCBs. Why are they so widespread in the electronics industry? The primary reason is historical. In the early days of electronics manufacturing, the green color of PCBs was a result of the solder mask material used – which happened to be green. Over time, this became the industry standard, and it’s now deeply ingrained in the electronics manufacturing process.

The green solder mask doesn’t offer any particular technical advantages over other colors. It’s all about convention and tradition. Manufacturers can choose various colors for solder masks depending on their needs, aesthetics, and branding.

In Conclusion

Circuit boards come in a rainbow of colors, each with its own significance and purpose. Whether it’s the classic green, the stylish black, or the vibrant red, the choice of PCB color is influenced by both tradition and modern aesthetics. Understanding the reasons behind these color choices can add an interesting dimension to the world of electronics.

For a more in-depth exploration of why PCBs are traditionally green, visit this article on why are circuit boards green.

So next time you open up your electronic device, take a moment to appreciate the color of the circuit board, as it may not only serve a functional purpose but also tell a story about the manufacturer’s choices and the device’s intended use.